Page 680 - Mastik®

P. 680

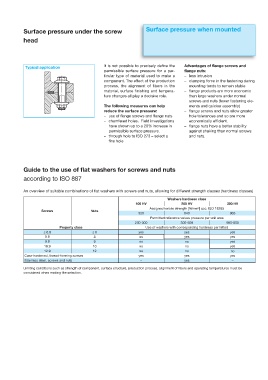

Surface pressure under the screw Surface pressure when mounted

head

It is not possible to precisely define the Advantages of flange screws and

Typical application

permissible surface pressure for a par- flange nuts:

ticular type of material used to make a – less intrusion

component. The effect of the production – clamping force in the fastening during

process, the alignment of fibers in the mounting tends to remain stable

material, surface finishing and tempera- – flange products are more economic

ture changes all play a decisive role. than large washers under normal

screws and nuts (fewer fastening ele-

The following measures can help ments and quicker assembly)

reduce the surface pressure: – flange screws and nuts allow greater

– use of flange screws and flange nuts hole tolerances and so are more

– chamfered holes. Field investigations economically efficient.

have shown up to a 20% increase in – flange nuts have a better stability

permissible surface pressure. against shaking than normal screws

– through hole to ISO 273 – select a and nuts.

fine hole

Guide to the use of flat washers for screws and nuts

according to ISO 887

An overview of suitable combinations of flat washers with screws and nuts, allowing for different strength classes (hardness classes)

Washers hardness class

100 HV 200 HV 300 HV

Assigned tensile strength [N/mm ] acc. ISO 18265

2

Screws Nuts

320 640 965

Permitted reference values pressure per unit area

200-300 300-500 500-800

Property class Use of washers with corresponding hardness permitted

≤ 6.8 ≤ 6 yes yes yes

8.8 8 no yes yes

9.8 9 no no yes

10.9 10 no no yes

12.9 12 no no no

Case-hardened, thread-forming screws yes yes yes

Stainless steel, screws and nuts – yes –

Limiting conditions such as strength of component, surface structure, production process, alignment of fibers and operating temperatures must be

considered when making the selection.