Page 685 - Mastik®

P. 685

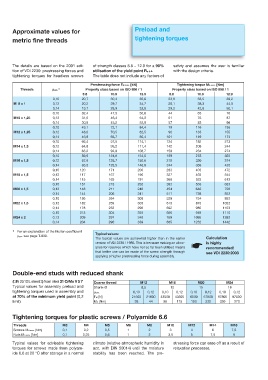

Approximate values for Preload and

metric fine threads tightening torques

The details are based on the 2001 edi- of strength classes 8.8 – 12.9 for a 90% safety and assumes the user is familiar

tion of VDI 2230: prestressing forces and utilisation of the yield point Rp 0.2. with the design criteria.

tightening torques for headless screws The table does not include any factors of

Prestressing force FM max. [kN] Tightening torque MA max. [Nm]

Threads μges. 1) Property class based on ISO 898 / 1 Property class based on ISO 898 / 1

8.8 10.9 12.9 8.8 10.9 12.9

0,10 20,7 30,4 35,6 22,8 33,5 39,2

M 8 x 1 0,12 20,2 29,7 34,7 26,1 38,3 44,9

0,14 19,7 28,9 33,9 29,2 42,8 50,1

0,10 32,4 47,5 55,6 44 65 76

M10 x 1,25 0,12 31,6 46,4 54,3 51 75 87

0,14 30,8 45,2 52,9 57 83 98

0,10 49,1 72,1 84,4 79 116 135

M12 x 1,25 0,12 48,0 70,5 82,5 90 133 155

0,14 46,8 68,7 80,4 101 149 174

0,10 66,4 97,5 114,1 124 182 213

M14 x 1,5 0,12 64,8 95,2 111,4 142 209 244

0,14 63,2 92,9 108,7 159 234 274

0,10 89,6 131,6 154,0 189 278 325

M16 x 1,5 0,12 87,6 128,7 150,6 218 320 374

0,14 85,5 125,5 146,9 244 359 420

0,10 120 171 200 283 403 472

M18 x 1,5 0,12 117 167 196 327 465 544

0,14 115 163 191 368 523 613

0,10 151 215 252 392 558 653

M20 x 1,5 0,12 148 211 246 454 646 756

0,14 144 206 241 511 728 852

0,10 186 264 309 529 754 882

M22 x 1,5 0,12 182 259 303 613 873 1022

0,14 178 253 296 692 985 1153

0,10 213 304 355 666 949 1110

M24 x 2 0,12 209 297 348 769 1095 1282

0,14 204 290 339 865 1232 1442

1) For an explanation of the friciton coefficient

Typical values:

μges. see page T.039.

The typical values are somewhat higher than in the earlier Calculation

version of VDI 2230 / 1986. This is because making an allow- is highly

ance for reserves which have not so far been utilised means recommended!

that better use can be made of the screw strength through see VDI 2230:2003

applying a higher prestressing force during assembly.

Double-end studs with reduced shank

(DIN 2510 L sheet 3) from steel 21 CrMo V 5 7 Coarse thread M12 M16 M20 M24

Typical values for assembly preload and Shank-Ø 8,5 12 15 18

tightening torques used in assembly and μges. 0,10 0,12 0,10 0,12 0,10 0,12 0,10 0,12

at 70% of the minimum yield point (0,2 FM [N] 21600 21600 43500 43500 6800 67800 97800 97800

limit) MA [Nm] 38 44 98 115 190 220 320 370

Tightening torques for plastic screws / Polyamide 6.6

Threads M3 M4 M5 M6 M8 M10 M12 M14 M16

Screws MA max. [Nm] 0,1 0,2 0,5 1 2 3 4 6 7,5

Nuts MA max. [Nm] 0,1 0,25 0,6 1 2 3,5 5 7,5 9

Typical values for advisable tightening climate (relative atmospheric humidity in stressing force can ease off as a result of

torques for screws made from polyam- acc. with DIN 50014) until the moisture relaxation processes.

ide 6.6 at 20 °C after storage in a normal stability has been reached. The pre-