Page 681 - Mastik®

P. 681

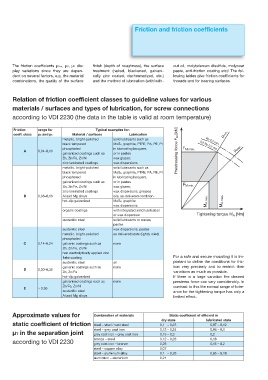

Friction and friction coefficients

The friction coefficients μGes, μG, μK dis- finish (depth of roughness), the surface out oil, molybdenum disulfide, molycoat

play variations since they are depen- treatment (naked, blackened, galvani- paste, anti-friction coating etc)! The fol-

dent on several factors, e.g. the material cally zinc coated, dachromatized, etc.) lowing tables give friction coefficients for

combinations, the quality of the surface and the method of lubrication (with/with- threads and for bearing surfaces.

Relation of friction coefficient classes to guideline values for various

materials / surfaces and types of lubrication, for screw connections

according to VDI 2230 (the data in the table is valid at room temperature)

Friction range for Typical examples for:

coeff. class μG and μK Material / surfaces Lubrication μ min.

metallic, bright-polished solid lubricants such as Rp 0,2 min.

black tempered MoS2, graphite, PTFE, PA, PE, Pl 0,9 Rp 0,2 min.

phosphated in lubricating lacquers, F M max. μ max.

A 0,04–0,10 Prestressing force F M [kN]

galvanized coatings such as or in pastes

Zn, Zn/Fe, Zn/Ni wax glazes;

zinc laminated coatings wax dispersions

metallic, bright-polished solid lubricants such as

black tempered MoS2, graphite, PTFE, PA, PE, Pl

phosphated in lubricating lacquers,

galvanized coatings such as or in pastes

F M min.

Zn, Zn/Fe, Zn/Ni wax glazes;

zinc laminated coatings wax dispersions, greases

B 0,08–0,16 Al and Mg alloys oils, as-delivered condition

hot-dip galvanized MoS2; graphite M A min. M A max.

wax dispersions

organic coatings with integrated solid lubrication

or wax dispersion Tightening torque M A [Nm]

austenitic steel solid lubricants or waxes;

pastes

austenitic steel wax dispersions, pastes

metallic, bright-polished as delivered state (lightly oiled)

phosphated

C 0,14–0,24 galvanic coatings such as none

Zn, Zn/Fe, Zn/Ni

non electrolytically applied zinc

flake coating For a safe and secure mounting it is im-

austenitic steel oil portant to define the conditions for fric-

galvanic coatings such as none tion very precisely and to restrict their

D 0,20–0,35

Zn, Zn/Fe variations as much as possible.

hot-dip galvanized If there is a large variation the desired

galvanised coatings such as none prestress force can vary considerably. In

Zn/Fe, Zn/Ni contrast to this the normal range of toler-

E ≥ 0,30

austenitic steel ance for the tightening torque has only a

Al and Mg alloys limited effect.

Approximate values for Combination of materials Static coefficient of efficient in

dry state lubricated state

static coefficient of friction steel – steel / cast steel 0,1 – 0,23 0,07 – 0,12

steel – grey cast iron 0,12 – 0,24 0,06 – 0,1

μT in the separation joint grey cast iron – grey cast iron 0,15 – 0,3 0,2

bronze – steel 0,12 – 0,28 0,18

according to VDI 2230 grey cast iron – bronze 0,28 0,15 – 0,2

steel – copper alloy 0,07

steel – aluminium alloy 0,1 – 0,28 0,05 – 0,18

aluminium – aluminium 0,21