Page 689 - Mastik®

P. 689

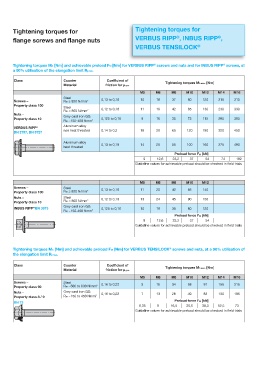

Tightening torques for Tightening torques for

®

®

flange screws and flange nuts VERBUS RIPP , INBUS RIPP ,

VERBUS TENSILOCK ®

®

®

Tightening torques MA [Nm] and achievable preload FM [Nm] for VERBUS RIPP screws and nuts and for INBUS RIPP screws, at

a 90% utilisation of the elongation limit Rp 0,2.

Class Counter Coefficient of

Tightening torques MA max. [Nm]

Material friction for μ ges.

M5 M6 M8 M10 M12 M14 M16

Steel

Screws – Rm ≥ 800 N/mm 2 0,13 to 0,16 10 18 37 80 120 215 310

Property class 100

Steel 0,12 to 0,18 11 19 42 85 130 230 330

Rm < 800 N/mm 2

Nuts –

Grey cast iron GG

Property class 10 0,125 to 0,16 9 16 35 75 115 200 300

Rm ~150-450 Nmm 2

Aluminum alloy

VERBUS RIPP ®

non heat threated 0,14 to 0,2 16 28 65 120 190 320 450

BN 2797, BN 9727

Aluminum alloy

0,13 to 0,18 14 25 55 100 160 275 400

heat threated

Preload force FM [kN]

9 12,6 23,2 37 54 74 102

Guideline values for achievable preload should be checked in field trials

M5 M6 M8 M10 M12

Screws – Steel 0,13 to 0,16 11 20 42 85 140

Property class 100 Rm ≥ 800 N/mm 2

Nuts – Steel 0,12 to 0,18 13 24 45 90 150

Rm < 800 N/mm 2

Property class 10

Grey cast iron GG

®

INBUS RIPP BN 3873 0,125 to 0,16 10 19 39 80 120

Rm ~150-450 Nmm 2

Preload force FM [kN]

9 12,6 23,2 37 54

Guideline values for achievable preload should be checked in field trials

Tightening torques MA [Nm] and achievable preload FM [Nm] for VERBUS TENSILOCK screws and nuts, at a 90% utilisation of

®

the elongation limit Rp 0,2.

Class Counter Coefficient of

Tightening torques MA max. [Nm]

Material friction for μ ges.

M5 M6 M8 M10 M12 M14 M16

Screws – Steel 0,16 to 0,22 9 16 34 58 97 155 215

Property class 90 Rm ~500 to 800 N/mm 2

Nuts – Grey cast iron GG 0,16 to 0,22 7 13 28 49 83 130 195

Property class 8 / 9 Rm ~150 to 450 Nmm 2

Preload force FM [kN]

BN 73

6,35 9 16,5 26,6 38,3 52,5 73

Guideline values for achievable preload should be checked in field trials