Page 691 - Mastik®

P. 691

Reference values for tightening torque Preload and

®

NORD-LOCK washers tightening torques

wedge-locking system

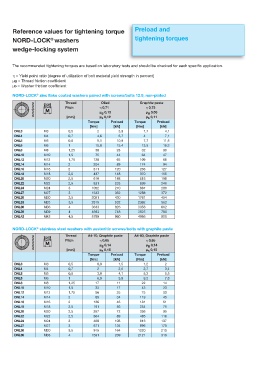

The recommended tightening torques are based on laboratory tests and should be checked for each specific application.

= Yield point ratio (degree of utilization of bolt material yield strength in percent)

μg = Thread friction coefficient

μs = Washer friction coefficient

®

NORD-LOCK zinc flake coated washers paired with screws/bolts 12.9, non-plated

w Thread 0,71 Graphite paste

Oiled

Pitch

0,75

μ g 0,08

μ g 0,13

[mm] μ s 0,12 μ s 0,11

Torque Preload Torque Preload

[Nm] [kN] [Nm] [kN]

DNL3 M3 0,5 2 3,9 1,7 4,1

DNL4 M4 0,7 4,6 6,7 4 7,1

DNL5 M5 0,8 9,1 10,9 7,7 11,5

DNL6 M6 1 15,8 15,4 13,5 16,3

DNL8 M8 1,25 38 28 32 30

DNL10 M10 1,5 75 44 64 47

DNL12 M12 1,75 128 65 109 68

DNL14 M14 2 204 89 174 94

DNL16 M16 2 311 120 263 127

DNL18 M18 2,5 437 148 370 156

DNL20 M20 2,5 610 188 515 198

DNL22 M22 2,5 831 233 699 246

DNL24 M24 3 1052 270 887 286

DNL27 M27 3 1533 352 1288 372

DNL30 M30 3,5 2091 430 1761 454

DNL33 M33 3,5 2815 532 2362 562

DNL36 M36 4 3633 626 3053 662

DNL39 M39 4 4683 748 3925 790

DNL42 M42 4,5 5799 860 4866 908

NORD-LOCK stainless steel washers with austenitic screws/bolts with graphite paste

®

w Thread A4-70, Graphite paste A4-80, Graphite paste

0,65

Pitch

0,65

μ g 0,14

μ g 0,14

[mm] μ s 0,15 μ s 0,15

Torque Preload Torque Preload

[Nm] [kN] [Nm] [kN]

DNL3 M3 0,5 0,9 1,5 1,2 2

DNL4 M4 0,7 2 2,6 2,7 3,4

DNL5 M5 0,8 3,9 4,1 5,3 5,5

DNL6 M6 1 6,9 5,9 9,2 7,8

DNL8 M8 1,25 17 11 22 14

DNL10 M10 1,5 33 17 43 23

DNL12 M12 1,75 56 25 75 33

DNL14 M14 2 89 34 119 45

DNL16 M16 2 136 46 181 61

DNL18 M18 2,5 191 56 254 75

DNL20 M20 2,5 267 72 356 95

DNL22 M22 2,5 364 89 485 118

DNL24 M24 3 460 103 613 137

DNL27 M27 3 671 134 895 179

DNL30 M30 3,5 915 164 1220 219

DNL36 M33 4 1591 239 2121 319