Page 695 - Mastik®

P. 695

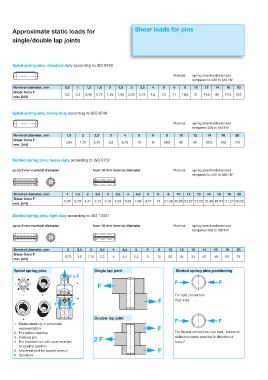

Approximate static loads for Shear loads for pins

single/double lap joints

Spiral spring pins, standard duty according to ISO 8750

Material: spring steel hardened and

tempered to 420 to 545 HV

Nominal diameter, mm 0,8 1 1,2 1,5 2 2,5 3 3,5 4 5 6 8 10 12 14 16 20

Shear force F

0,2 0,3 0,45 0,72 1,25 1,95 2,25 3,75 4,8 7,5 11 19,5 31 44,5 60 77,5 125

min. [kN]

Spiral spring pins, heavy duty according to ISO 8748

Material: spring steel hardened and

tempered 420 to 545 HV

Nominal diameter, mm 1,5 2 2,5 3 4 5 6 8 10 12 14 16 20

Shear force F

0,95 1,75 2,75 3,8 6,75 10 15 26,5 42 60 82,5 105 170

min. [kN]

Slotted spring pins, heavy duty according to ISO 8752

up to 8 mm nominal diameter from 10 mm nominal diameter Material: spring steel hardened and

tempered to 420 to 560 HV

Nominal diameter, mm 1 1,5 2 2,5 3 3,5 4 4,5 5 6 8 10 12 13 14 16 18 20

Shear force F

0,35 0,79 1,41 2,19 3,16 4,53 5,62 7,68 8,77 13 21,38 35,08 52,07 57,55 72,36 85,51 111,27 140,32

min. [kN]

Slotted spring pins, light duty according to ISO 13337

up to 8 mm nominal diameter from 10 mm nominal diameter Material: spring steel hardened and

tempered 420 to 560 HV

Nominal diameter, mm 2 2,5 3 3,5 4 4,5 5 6 8 10 12 13 14 16 18 20

Shear force F

0,75 1,2 1,75 2,3 4 4,4 5,2 9 12 20 24 33 42 49 63 79

min. [kN]

Sprial spring pins Single lap joint Slotted spring pins positioning

2 x F

F F

F

For rigid connection

F High load

F F

Double lap joint

F F

1. Radial elasticity in schematic

representation F

2. Pin before inserting For flexible connection, low load, minimum

3. Inserted pin 2 F deflection paths possible in direction of

4. Pin knocked out with coils reverted force F

to original position

5. Universal joint for socket wrench F

6. Spiral pin