Page 696 - Mastik®

P. 696

Direct assembly into metals using Construction recommendations

thread forming screws

according to DIN 7500

What should be considered in the de- r /P PUIFS TBGFUZ GFBUVSFT TVDI BT SF systems integrated into the surface

sign and construction processes? taining rings) are necessary. Resis- protection and/or an additional lubri-

r 5ISFBE GPSNJOH TDSFXT UP %*/ tance to vibration is provided by the cant can be used.

(trilobular) produce a chip-free, gauge- thread friction. r 5IFSF JT B SJTL PG GBJMVSF EVF UP IZESP

correct metric internal thread. r 5IFZ DBO CF SF VTFE m UJNFT gen embrittlement for thread-form-

r 5IF TDSFXT BSF IFBU USFBUFE UP HJWF B r 'PS UIJO TIFFUT UIF VTF PG QVODI ing screws with galvanic coatings.

2

tensile strength in use of ca. 800 N/mm . holes can help improve the mechani- A treatment must be carried out ac-

r *U JT QPTTJCMF UP GPSN UISFBET JO EVDUJMF cal properties of the fastening. cording to ISO 4042 to reduce the

metals such as steel, non-ferrous met- r *U JT SFDPNNFOEFE UIBU QSFMJNJOBSZ USJ risk of hydrogen embrittlement. High-

als and light metals up to ca. 140–160 als be made for «laser-bored» holes strength screws with property classes

HV. (the cut surfaces may be to hard.) 8.8 and higher must not be replaced

r 5ISFBE GPSNJOH JT OPU TVJUBCMF GPS CSJU r 1SFMJNJOBSZ USJBMT TIPVME CF NBEF GPS by case-hardened thread-forming

tle metals such as grey cast iron. critical applications. Get in touch with screws without an adequate examina-

r 5ISFBE GPSNJOH TDSFXT NBEF GSPN Bossard Engineering as early as pos- tion.

A2 stainless steel can only safely be sible in the development stage of your Functionally appropriate design of

screwed into light metals. In doing product. components and selection of the cor-

this the size of the pilot holes must r 'PS UIF GVODUJPOBM GVMGJMMNFOU PG B rect type of fastening element are

be 5% larger than the values in the thread-forming screw a suitable lubri- essential requirements for a secure

table. cation should be applied. Lubrication screw connection.

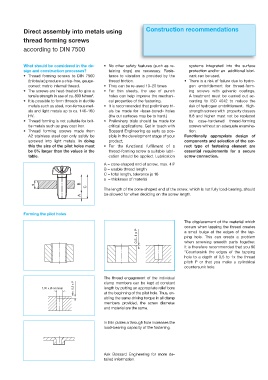

A = cone-shaped end of screw, max. 4 P

B = usable thread length

C = total length, tolerance js 16

s = thickness of material

s B

C

The length of the cone-shaped end of the screw, which is not fully load-bearing, should

A be allowed for when deciding on the screw length.

Forming the pilot holes

The displacement of the material which

occurs when tapping the thread creates

0,5–1 x P a small bulge at the edges of the tap-

ping hole. This can create a problem

when screwing smooth parts together.

It is therefore recommended that you 90

°Countersink the edges of the tapping

hole to a depth of 0,5 to 1x the thread

pitch P or that you make a cylindrical

countersunk hole.

The thread engagement of the individual

1,05 x Ø-nominal min. 0,5 x P clamp members can be kept at constant

length by putting an appropriate relief bore

at the beginning of the pilot hole. Thus, en-

abling the same driving torque in all clamp

members provided, the screw diameter

and material are the same.

In thin plates a through hole increases the

load-bearing capacity of the fastening.

Ask Bossard Engineering for more de-

tailed information.