Page 701 - Mastik®

P. 701

Direct assembly in thermoplastics Construction recommendations

®

using PT / eco-syn screws

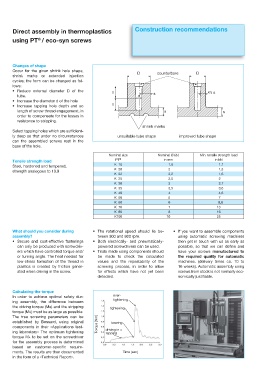

Changes of shape

Occur for the given shrink hole shape, D counterbore D

shrink marks or extended injection

cycles; the form can be changed as fol-

lows:

r 3FEVDF FYUFSOBM EJBNFUFS % PG UIF ll s 2 /3 s

tube. d

r *ODSFBTF UIF EJBNFUFS E PG UIF IPMF ll

r *ODSFBTF UBQQJOH IPMF EFQUI BOE TP

length of screw thread engagement, in s s

order to compensate for the losses in

resistance to stripping.

shrink marks

Select tapping holes which are sufficient-

ly deep so that under no circumstances unsuitable tube shape improved tube shape

can the assembled screws rest in the

base of the hole.

Nominal size Nominal Ø (d1) Min. tensile strength load

PT ® in mm in kN

Tensile strength load

K 18 1,8 1,1

Steel, hardened and tempered,

K 20 2 1,3

strength analogous to 10.9

K 22 2,2 1,6

K 25 2,5 2

K 30 3 2,7

K 35 3,5 3,6

K 40 4 4,6

K 50 5 7

K 60 6 9,8

K 70 7 13

K 80 8 16

K100 10 25

What should you consider during r 5IF SPUBUJPOBM TQFFE TIPVME MJF CF r *G ZPV XBOU UP BTTFNCMF DPNQPOFOUT

assembly? tween 300 and 800 rpm. using automatic screwing machines

r 4FDVSF BOE DPTU FGGFDUJWF GBTUFOJOHT r #PUI FMFDUSJDBMMZ BOE QOFVNBUJDBMMZ then get in touch with us as early as

can only be produced with screwdriv- powered screwdrivers can be used. possible, so that we can define and

ers which have controlled torque and/ r 5SJBMT NBEF VTJOH DPNQPOFOUT TIPVME have your screws manufactured to

or turning angle. The heat needed for be made to check the calculated the required quality for automatic

low-stress formation of the thread in values and the repeatability of the machines. (delivery times ca. 10 to

plastics is created by friction gener- screwing process, in order to allow 16 weeks). Automatic assembly using

ated when driving in the screw. for effects which have not yet been screws from stock is not normally eco-

detected. nomically justifiable.

Calculating the torque

In order to achieve optimal safety dur- over-

tightening

ing assembly, the difference between

the driving torque (Me) and the stripping tightening

torque (Mü) must be as large as possible.

The true screwing parameters can be

established by Bossard, using original Torque [Nm] bearing

components in their «Applications test-

ing laboratory» The optimum tightening driving in =

tapping

torque MA to be set on the screwdriver

for the assembly process is determined

based on customer-specific require-

ments. The results are then documented Time [sec]

in the form of a «Technical Report».