Page 704 - Mastik®

P. 704

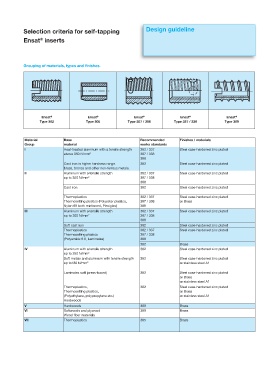

Selection criteria for self-tapping Design guideline

®

Ensat inserts

Grouping of materials, types and finishes.

Ensat ® Ensat ® Ensat ® Ensat ® Ensat ®

Type 302 Type 305 Type 307 / 308 Type 337 / 338 Type 309

Material Base Recommended Finishes / materials

Group material works standards

I Heat-treated aluminum with a tensile strength 302 / 337 Steel case-hardened zinc plated

above 350 N/mm 307 / 338

2

308

Cast iron in higher hardness range. 302 Steel case-hardened zinc plated

brass, bronze and other non-ferrous metals.

II Aluminum with a tensile strength 302 / 337 Steel case-hardened zinc plated

2

up to 350 N/mm 307 / 338

308

Cast iron 302 Steel case-hardened zinc plated

Thermoplastics 302 / 337 Steel case-hardened zinc plated

Thermosetting plastics (Polyester plastics, 307 / 338 or Brass

Nylon 66 both reinforced, Plexiglas) 308

III Aluminum with a tensile strength 302 / 337 Steel case-hardened zinc plated

2

up to 300 N/mm 307 / 338

308

Soft cast iron 302 Steel case-hardened zinc plated

Thermoplastics 302 / 337 Steel case-hardened zinc plated

Thermosetting plastics 307 / 338

(Polyamide 6.6, Laminates) 308

302 Brass

IV Aluminum with a tensile strength 302 Steel case-hardened zinc plated

up to 250 N/mm 2

Soft metals and aluminum with tensile strength 302 Steel case-hardened zinc plated

up to180 N/mm 2 or stainless steel A1

Laminates soft (press-board) 302 Steel case-hardened zinc plated

or Brass

or stainless steel A1

Thermoplastics, 302 Steel case-hardened zinc plated

Thermosetting plastics, or Brass

(Polyethylene, polypropylene etc.) or stainless steel A1

Hardwoods

V Hardwoods 309 Brass

VI Softwoods and plywood 309 Brass

Wood fiber materials

VII Thermoplastics 305 Brass