Page 702 - Mastik®

P. 702

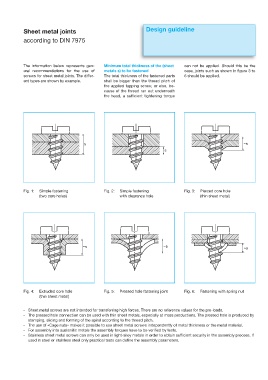

Sheet metal joints Design guideline

according to DIN 7975

The information below represents gen- Minimum total thickness of the (sheet can not be applied. Should this be the

eral recommendations for the use of metals s) to be fastened case, joints such as shown in figure 3 to

screws for sheet metal joints. The differ- The total thickness of the fastened parts 6 should be applied.

ent types are shown by example. shall be bigger than the thread pitch of

the applied tapping screw; or else, be-

cause of the thread run out underneath

the head, a sufficient tightening torque

s ~s

s

Fig. 1: Simple fastening Fig. 2: Simple fastening Fig. 3: Pierced core hole

(two core holes) with clearance hole (thin sheet metal)

~s ~s ~s

Fig. 4: Extruded core hole Fig. 5: Pressed hole fastening joint Fig. 6: Fastening with spring nut

(thin sheet metal)

– Sheet metal screws are not intended for transferring high forces. There are no reference values for the pre-loads.

– The pressed hole connection can be used with thin sheet metals, especially at mass productions. The pressed hole is produced by

stamping, slicing and forming of the spiral according to the thread pitch.

– The use of «Cage nuts» makes it possible to use sheet metal screws independently of metal thickness or the metal material.

– For assembly into austenitic metals the assembly torques have to be verified by tests.

– Stainless sheet metal screws can only be used in light-alloy metals in order to obtain sufficient security in the assembly process. If

used in steel or stainless steel only practical tests can define the assembly parameters.