Page 700 - Mastik®

P. 700

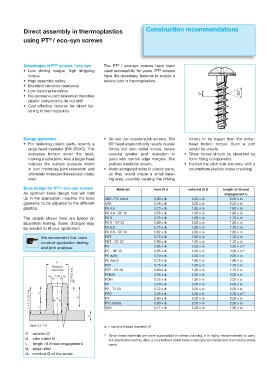

Direct assembly in thermoplastics Construction recommendations

®

using PT / eco-syn screws

®

®

Advantages of PT screws / eco-syn The PT / eco-syn screws have been

r -PX ESJWJOH UPSRVF IJHI TUSJQQJOH used successfully for years. PT screws

®

torque have the necessary features to enable a

r )JHI BTTFNCMZ TBGFUZ secure joint in thermoplastics.

r &YDFMMFOU WJCSBUJPO SFTJTUBODF

r -PX CVSTUJOH UFOEFODZ

P 30°

r /P FYDFTTJWF KPJOU SFMBYBUJPO UIFSFGPSF

plastic components do not shift

r Cost-effective fastener for direct fas-

tening in thermoplastics

Design guidelines r %P OPU VTF DPVOUFSTVOL TDSFXT 5IF torque to be bigger than the under-

r 'PS GBTUFOJOH QMBTUJD QBSUT TQFDJGZ B 90° head angle not only results in axial head friction torque. Such a joint

large head diameter (BN 20040). This forces but also radial forces, hence would be unsafe.

increases friction under the head, causing greater joint relaxation in r 4IFBS GPSDFT TIPVME CF BCTPSCFE CZ

making a safer joint. Also a larger head parts with narrow edge margins. The form-fitting components.

reduces the surface pressure which preload would be unsafe. r 'VSOJTI UIF QJMPU IPMF FOUSBODF XJUI B

in turn minimizes joint relaxation and r "WPJE FMPOHBUFE IPMFT JO QMBTUJD QBSUT counterbore (avoids stress cracking)

ultimately increases the residual clamp as they would create a small bear-

load. ing area, possibly causing the driving

®

Boss design for PT / eco-syn screws Material hole Ø d external Ø D length of thread

An optimum boss design that will hold engagement te

up in the application, requires the boss ABS / PC blend 0,80 x d1 2,00 x d1 2,00 x d1

geometry to be adjusted to the different ASA 0,78 x d1 2,00 x d1 2,00 x d1

plastics. PA 4.6 0,73 x d1 1,85 x d1 1,80 x d1

PA 4.6 - GF 30 0,78 x d1 1,85 x d1 1,80 x d1

The details shown here are based on PA 6 0,75 x d1 1,85 x d1 1,70 x d1

laboratory testing. Some changes may PA 6 - GF 30 0,80 x d1 2,00 x d1 1,90 x d1

be needed to fit your application. PA 6.6 0,75 x d1 1,85 x d1 1,70 x d1

PA 6.6 - GF 30 0,82 x d1 2,00 x d1 1,80 x d1

We recommend that users PBT 0,75 x d1 1,85 x d1 1,70 x d1

conduct application testing PBT - GF 30 0,80 x d1 1,80 x d1 1,70 x d1

PC 1)

and joint analyses. 0,85 x d1 2,50 x d1 2,20 x d1

PC - GF 30 0,85 x d1 2,20 x d1 2,00 x d1 1)

PE (soft) 0,70 x d1 2,00 x d1 2,00 x d1

PE (hard) 0,75 x d1 1,80 x d1 1,80 x d1

D

PET

Pressure 0,75 x d1 1,85 x d1 1,70 x d1

0,3–0,5 x d 1 PMMA 0,85 x d1 2,00 x d1 2,00 x d1

relief hole PET - GF 30 0,80 x d1 1,80 x d1 1,70 x d1

de = 1,05 x d 1 POM 0,75 x d1 1,95 x d1 2,00 x d1

PP 0,70 x d1 2,00 x d1 2,00 x d1

PP - TV 20 0,72 x d1 2,00 x d1 2,00 x d1 1)

L = 1,1–1,2 x te = d t e PS 0,85 x d1 2,50 x d1 2,20 x d1

PPO

=

0,80 x d1

2,00 x d1

2,00 x d1

PVC (hard)

0,80 x d1

2,00 x d1

2,00 x d1

SAN

s 0,77 x d1 2,00 x d1 1,90 x d1

Taper 0,5–1,0°

d1 = nominal thread diameter Ø

D outside Ø 1) Since these materials are more susceptible to stress cracking, it is highly recommended to carry

d pilot holed Ø out application testing. Also, a counterbore (relief bore) is strongly recommended to minimize stress

t e length of thread engagement risers.

d e edge relief

d 1 nominal Ø of the screw