Page 697 - Mastik®

P. 697

Direct assembly into metals using Construction recommendations

thread forming screws

according to DIN 7500

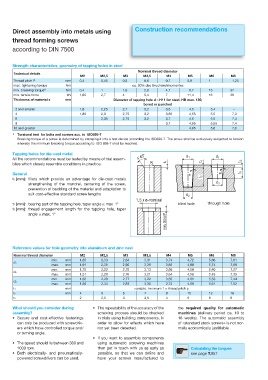

Strength characteristics, geometry of tapping holes in steel

Nominal thread diameter

Technical details

M2 M2,5 M3 M3,5 M4 M5 M6 M8

Thread pitch P mm 0,4 0,45 0,5 0,6 0,7 0,8 1 1,25

max. tightening torque Nm ca. 80% des Bruchdrehmomentes

min. breaking torque 1) Nm 0,4 1 1,8 2,8 4,1 8,7 15 37

min. tensile force kN 1,65 2,7 4 5,4 7 11,4 16 29

Thickness of material s mm Diameter of tapping hole d – H11 for steel, HB max. 135;

bored or punched

2 and smaller 1,8 2,25 2,7 3,2 3,6 4,5 5,4 –

4 1,85 2,3 2,75 3,2 3,65 4,55 5,5 7,3

6 2,35 2,75 3,2 3,7 4,6 5,5 7,4

8 3,7 4,65 5,55 7,4

10 and greater 4,65 5,6 7,5

1) Torsional test for bolts and screws acc. to ISO898-7

Breaking torque of a screw is determined by clamping it into a test device according the ISO898-7. The screw shall be exclusively subjected to torsion

whereby the minimum breaking torque according to ISO 898-7 shall be reached..

Tapping holes for die-cast metal

All the recommendations must be tested by means of trial assem-

blies which closely resemble conditions in practice.

General

t1 [mm]: fillets which provide an advantage for die-cast metals

strengthening of the mandrel, centering of the screw,

prevention of buckling of the material and adaptation to

suit cost-effective standard screw lengths

t2 [mm]: bearing part of the tapping hole, taper angle max. 1° blind hole through hole

t3 [mm]: thread engagement length for the tapping hole, taper

angle max. 1°

Reference values for hole geometry into aluminium and zinc cast

Nominal thread diameter M2 M2,5 M3 M3,5 M4 M5 M6 M8

min. mm 1,85 2,33 2,84 3,31 3,74 4,72 5,66 7,61

d1

max. mm 1,91 2,39 2,90 3,39 3,82 4,80 5,74 7,69

min. mm 1,75 2,22 2,70 3,13 3,56 4,50 5,40 7,27

d2

max. mm 1,81 2,28 2,76 3,21 3,64 4,58 5,48 7,35

min. mm 1,80 2,28 2,77 3,22 3,65 4,61 5,53 7,44

d3

max. mm 1,86 2,34 2,83 3,30 3,73 4,69 5,61 7,52

t1 mm variable, minimum 1 x thread pitch p

t2 mm 4 5 6 7 8 10 12 16

t3 2 2,5 3 3,5 4 5 6 8

What should you consider during r 5IF SFQFBUBCJMJUZ PG UIF BDDVSBDZ PG UIF the required quality for automatic

assembly? screwing process should be checked machines (delivery period ca. 10 to

r 4FDVSF BOE DPTU FGGFDUJWF GBTUFOJOHT in trials using building components, in 16 weeks). The automatic assembly

can only be produced with screwdriv- order to allow for effects which have of «standard stock screws» is not nor-

ers which have controlled torque and/ not yet been detected. mally economically justifiable.

or turning angle.

r *G ZPV XBOU UP BTTFNCMF DPNQPOFOUT

r 5IF TQFFE TIPVME MJF CFUXFFO BOE using automatic screwing machines

1000 rpm. then get in touch with us as early as Calculating the torques

r #PUI FMFDUSJDBMMZ BOE QOFVNBUJDBMMZ possible, so that we can define and see page T.057

powered screwdrivers can be used. have your screws manufactured to