Page 693 - Mastik®

P. 693

Summary of constructive measures for Securely fastened joints

locking screw joints

In principle, there are two reasons why bolted connections may need locking

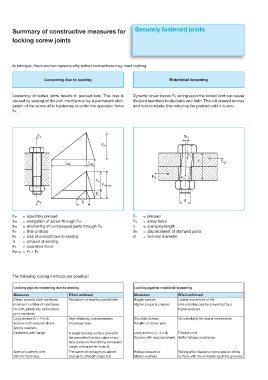

Loosening due to seating Rotational loosening

Loosening of bolted joints results in preload loss. This loss is Dynamic shear forces FQ acting upon the bolted joint can cause

caused by seating of the joint members or by a permanent elon- the joint members to slip back and forth. This will prompt screws

gation of the screw after tightening or under the operation force and nuts to rotate, this reducing the preload until it is zero.

FA.

F A S G

F M

F V

l K F Q

f SM f pM

F Q F V

F V

F M min.

F Z

d

F A f Z

FM = assembly preload FV = preload

fSM = elongation of screw through FM FQ = shear force

fPM = shortening of compressed parts through FM lK = clamping length

FV = final preload SG = displacement of clamped parts

FZ = loss of preload due to seating d = nominal diameter

fZ = amount of seating

FA = operation force

FM min. = FV + FZ

The following locking methods are possible:

Locking against loosening due to seating Locking against rotational loosening

Measures Effect achieved Measures Effect achieved

Clean, smooth joint interfaces Reduction of seating possibilities. Bigger screws Lateral movement of the

minimum number of interfaces Higher property classes joint member can be prevented by a

No soft, plastically deformable higher preload.

joint members

Long screws (lK > 4 x d). High elasticity, compensation Shoulder screws No possibility for lateral movements

Screws with reduced shank of preload loss. Parallel or dowel pins

Spring washers

Fasteners with flange A larger bearing surface prevents Long screws (l > 4 x d) Flexible joint

the permitted limiting value of sur- Screws with reduced shank Better fatigue resistance.

face pressure from being exceeded.

Larger tolerance for hole-Ø.

Special washers with The same advantages as above. Ribbed screws or Rolling effect leads to compression of the

200 HV hardness. Use up to strength class 8.8. ribbed washers. surface with the embedding of the grooves.